Induction sealing machines are widely used in the packaging industry to seal containers with a tamper-evident seal. These machines use electromagnetic induction to heat a metallic foil liner, which is placed over the mouth of the container. The heat melts the adhesive on the liner, which then bonds to the rim of the container, creating a hermetic seal.

Induction sealing machines are commonly used in the food and beverage industry, pharmaceuticals, and other industries that require secure packaging. The process is fast, efficient, and provides a reliable seal that is resistant to tampering and contamination.

How Induction Sealing Machines Work

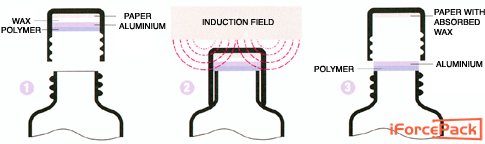

Induction sealing machines use a process known as electromagnetic induction to seal containers. The machine consists of an induction coil, which generates an electromagnetic field when energized with an alternating current. When the container with the foil liner passes through the electromagnetic field, the liner heats up due to eddy currents induced by the field.

Induction sealing machines are used to seal containers with foil or laminate liners. The process works by creating an electromagnetic field that heats the foil liner and melts it onto the container's rim. The result is an airtight seal that prevents leakage, contamination, and tampering.

Here's a step-by-step breakdown of how induction sealing machines work:

1.The container is filled with the product and capped with a foil or laminate liner. The liner is typically made of a thin layer of aluminum foil bonded to a layer of polymer film.

2.The capped container is placed on the sealing head of the induction sealing machine.

3.The machine creates an electromagnetic field using an induction coil, which is located under the sealing head.

4.The electromagnetic field heats the foil liner, causing it to melt and bond to the container's rim.

5.The machine applies pressure to the sealing head to ensure a tight seal.

6.The container is then cooled to solidify the seal.

The entire process is quick and efficient, with seals being created in a matter of seconds. Induction sealing machines are commonly used in the food and beverage industry for products such as dairy, juices, sauces, and condiments. They are also used in the pharmaceutical industry for medications, and in the cosmetic industry for products such as lotions and creams. The benefits of using induction sealing machines include improved product shelf life, reduced risk of contamination, and tamper-evident packaging.

The heat melts the adhesive on the liner, which then bonds to the rim of the container, creating a hermetic seal. The process is fast, efficient, and provides a reliable seal that is resistant to tampering and contamination.

Types of Induction Sealing Machines

Induction sealing machines are available in different sizes and configurations to accommodate different container sizes and production volumes. There are three main types of induction sealing machines:

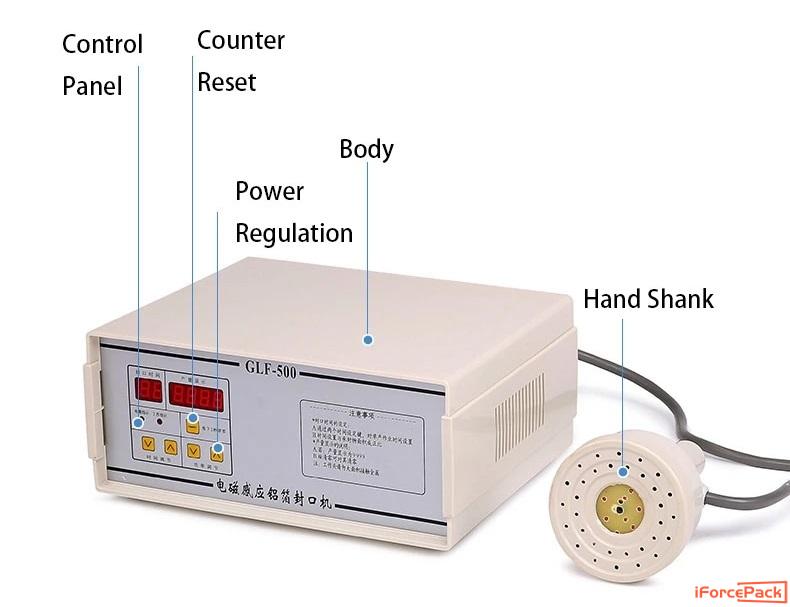

1.Manual Induction Sealing Machines: These machines are designed for low-volume production and are manually operated. They are suitable for small businesses that do not require high-speed production.

2.Semi-Automatic Induction Sealing Machines: These machines are designed for medium-volume production and are partially automated. They require some manual intervention, such as placing the container on the machine and removing the sealed container.

3.Automatic Induction Sealing Machines: These machines are designed for high-volume production and are fully automated. They can sort, feed, seal, and close the containers without any manual intervention.

Features of Induction Sealing Machines

In addition to sealing, some induction sealing machines come with additional features such as cap sorting, cap feeding, and cap closing. Cap sorting helps to align the caps in the correct orientation, while cap feeding ensures a continuous supply of caps for sealing. Cap closing ensures that the caps are tightened to the correct torque to prevent leaks.

Benefits of Induction Sealing Machines

Induction sealing machines provide several benefits over other sealing methods. These benefits include:

1.Tamper-evident seals: Induction seals provide a tamper-evident seal that prevents unauthorized access to the product. Any attempt to remove the seal will result in damage to the seal, indicating that the product has been tampered with.

2.Contamination prevention: Induction seals provide a hermetic seal that prevents contamination of the product. This is especially important in the food and beverage industry, where contamination can lead to serious health issues.

3.Cost-effective: Induction sealing machines are cost-effective compared to other sealing methods. They require minimal maintenance and can seal a large number of containers in a short period.

Conclusion

Induction sealing machines are a reliable and efficient method of sealing containers with a tamper-evident seal. They are widely used in the packaging industry to seal containers in the food and beverage industry, pharmaceuticals, and other industries that require secure packaging. Induction sealing machines are available in different sizes and configurations to accommodate different container sizes and production volumes. They provide several benefits over other sealing methods, including tamper-evident seals, contamination prevention, and cost-effectiveness.

Contact: iForcePack

Phone: +86-198 7511 8892

E-mail: info@iforcepack.com

Add: J101,Haitang,Siji huacheng, Bantian Street, Longgang District, Shenzhen, Guangdong, China