In the evolving landscape of manufacturing and packaging industries, achieving high efficiency and productivity is paramount for success. One key aspect that significantly impacts these factors is the quality of cap sealing and closure. To ensure product integrity, freshness, and prevention of leakage, cap wadding machines have emerged as a game-changer. Revolutionizing the manufacturing and packaging process, these machines automate the insertion of liners or wads into caps, providing a robust seal and ensuring the safety of the contents.

Understanding Cap Wadding Machines:

Cap wadding machines are specialized devices designed specifically for the insertion of wads into caps or closures. These machines are carefully engineered to streamline the cap manufacturing and packaging process, reducing manual labor while significantly improving productivity. As the demand for precision and speed increases, cap wadding machines have gained prominence across various industries, including food and beverage, pharmaceuticals, cosmetics, and chemical manufacturing.

The Importance of Wads in Cap Sealing:

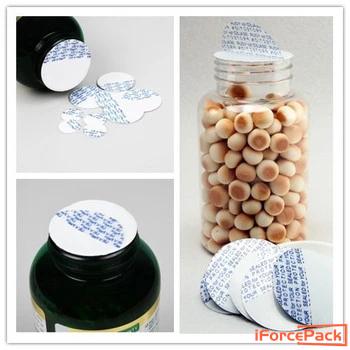

Wads, also known as liners or seals, are a vital component of cap sealing systems. They play a crucial role in maintaining product freshness, preventing leakage, tamper evidence, and ensuring seal integrity. The cap wadding machines precisely insert these wads into caps, facilitating a secure and tamper-evident seal. This not only ensures consumer safety and convenience but also enhances the overall product presentation, increasing customer satisfaction and brand reputation.

Advantages and Features of Cap Wadding Machines:

1.Efficiency and Speed: Cap wadding machines are designed to handle large volumes of caps, significantly reducing manual labor and increasing production speed. These machines can insert wads into caps at an impressive rate, ensuring seamless manufacturing and packaging operations.

2.Precision and Accuracy: With advanced automation technology, cap wadding machines offer precise and accurate wad insertion. This eliminates human errors and inconsistencies, ensuring each cap receives a uniform and reliable seal.

3.Versatility: Cap wadding machines are adaptable to various cap sizes and shapes, allowing manufacturers to cater to different product requirements. From small beverage caps to larger pharmaceutical closures, these machines provide versatility in the production process.

4.Quality Control: Cap wadding machines incorporate quality control mechanisms that detect and reject caps with faulty seals or missing wads. This ensures that only caps meeting the highest standards are passed along the production line, enhancing product quality and minimizing wastage.

5.Cost Savings: Investing in cap wadding machines brings long-term cost savings. By reducing manual labor and increasing production efficiency, manufacturers can achieve higher output with reduced operational costs, leading to improved profitability.

There are several different types of cap wadding machines available in the market, each designed to meet specific requirements and cap sealing applications. Some common types include:

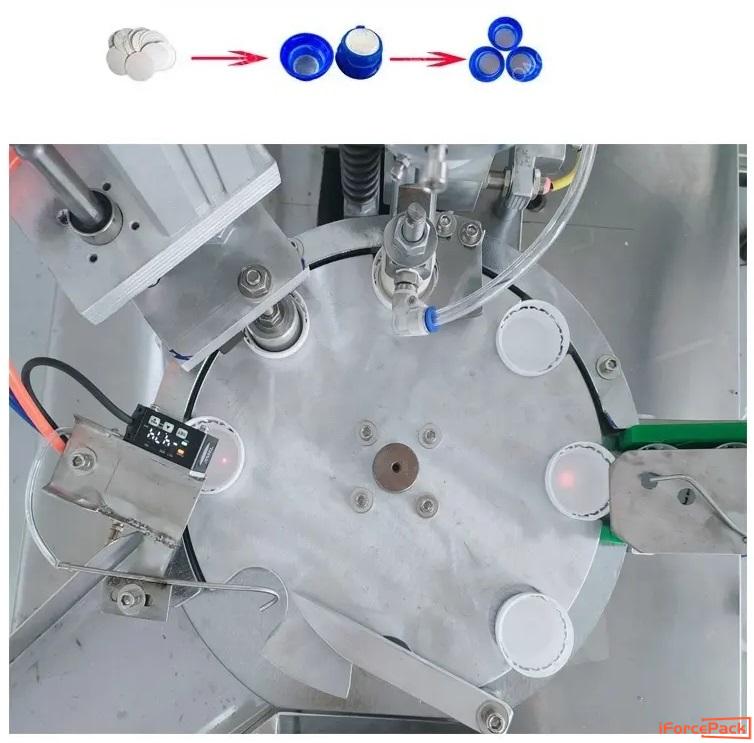

1.Rotary Cap Wadding Machines: These machines operate in a rotary motion and can handle high volumes of caps. They are designed for continuous production lines, offering high-speed wad insertion and seamless integration with other packaging machinery.

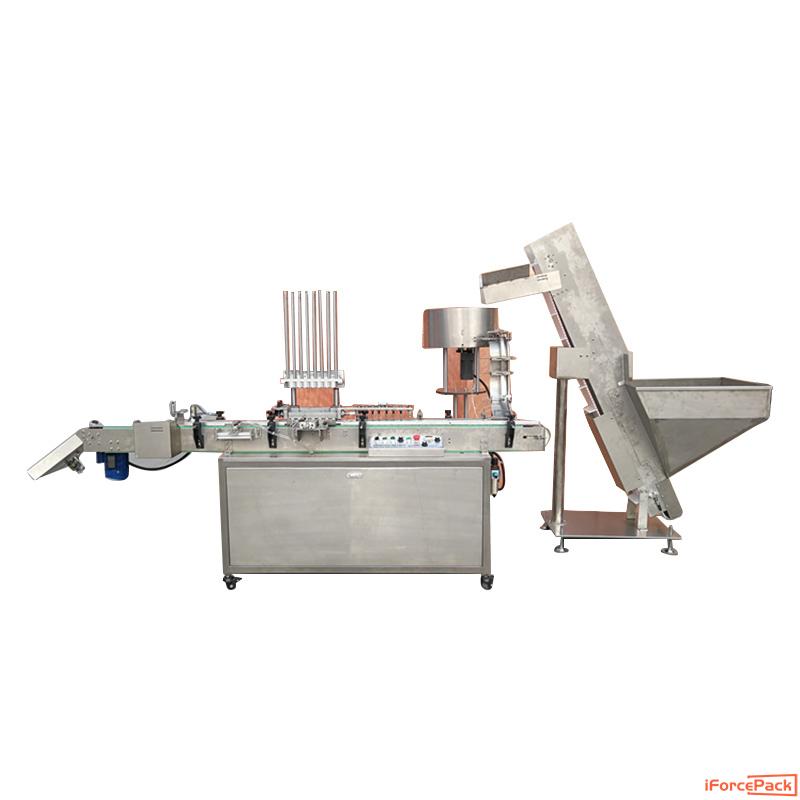

2.Linear Cap Wadding Machines: Linear cap wadding machines operate in a linear fashion, suitable for smaller to medium-sized production needs. They are versatile and can handle various cap sizes and shapes with precision.

The working flow of a cap wadding machine typically involves several steps to ensure efficient and accurate wad insertion. The specific working flow may vary depending on the type and configuration of the machine, but it generally follows these basic steps:

Cap Feeding: In this step, caps are fed into the machine through a hopper or input mechanism. The machine may have various methods for cap feeding, such as a vibrating feeder, conveyor belt, or manual loading.

1.Wad Insertion: After caps are properly positioned, the machine's wad insertion mechanism comes into play. This mechanism retrieves wads from a wad supply or dispenser and accurately places them onto the caps. The wads can be pre-cut or cut from a continuous roll, depending on the machine design.

2.Pressing or Application of Pressure: Once the wads are inserted onto the caps, the machine applies pressure to ensure proper sealing. This may involve a press or compressing mechanism that firmly presses the wad against the cap and container opening, creating a tight seal.

3.Cap Discharge: After the wad insertion and sealing process, the capped containers move along the machine's conveyor or transfer system to the next stage of the packaging line. The machine may have a discharge chute, conveyor belt, or robotic arm to transfer the finished caps to the subsequent packaging or labeling process.

4.Monitoring and Control: Throughout the working flow, the machine monitors and controls various parameters to ensure consistent and accurate wad insertion. This includes sensors for detecting cap and wad positioning, monitoring pressure levels, and controlling the overall machine operations.

It is important to note that the specific working flow may differ based on the type of cap wadding machine and its features. Some machines may incorporate additional steps, such as cap orientation, cap sterilization, or quality inspection. Manufacturers provide detailed operating manuals and instructions for each specific machine model to guide users through the working flow.

These are just a few examples of the various types of cap wadding machines available. Each type has its own set of advantages and can be tailored to meet specific production needs, ensuring optimal cap sealing efficiency and productivity.

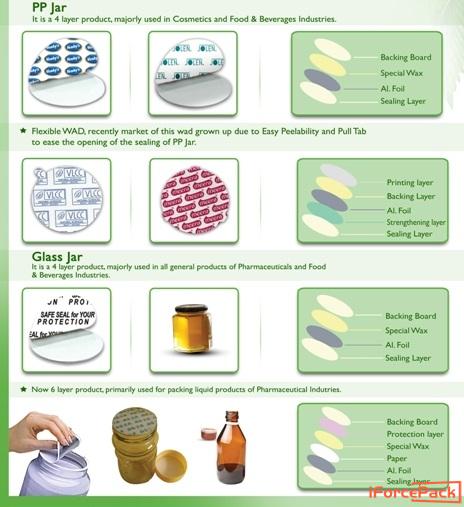

There are different types of wadding caps available, which are used to provide a seal or barrier between the cap and the product inside the container. Some common types of wadding caps include:

1.Foam Wadding Caps: These caps have a foam liner inserted in the cap, providing a cushioning effect and preventing leakage or spillage. Foam wadding caps are commonly used for liquid products or products that need to be kept airtight.

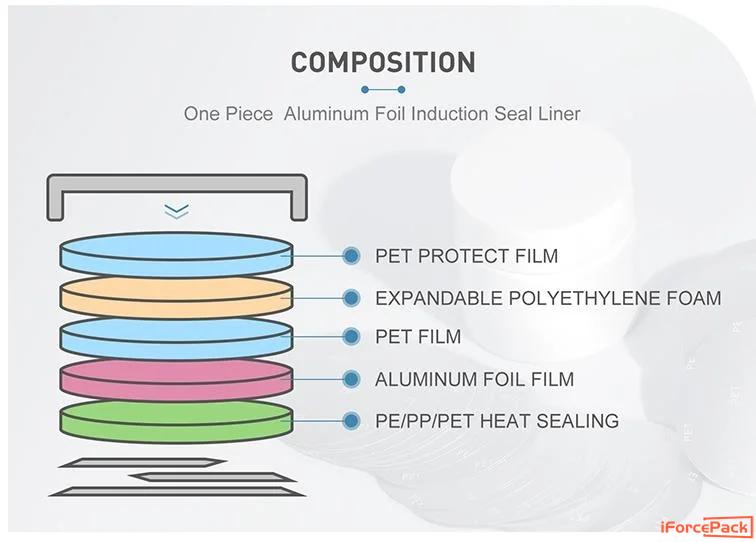

2.Induction Seal Wadding Caps: These caps have a foil liner that creates a hermetic seal when exposed to heat induction. The foil liner is placed inside the cap, and when the cap is applied to the container and heated, the foil adheres to the container's rim, providing tamper-evident and leak-proof sealing.

3.Pressure Sensitive Wadding Caps: These caps have a pressure-sensitive liner that adheres to the container rim when pressure is applied. The liner is typically made of a material like PET or foam coated with an adhesive. When the cap is applied and tightened, the pressure-sensitive liner creates a secure seal.

4.Tear-off Wadding Caps: These caps have a liner that can be easily torn off when the cap is opened for the first time. This type of wadding cap is commonly used for products like pharmaceuticals or food items that require tamper-evident packaging.

5.Heat Seal Wadding Caps: These caps have a heat-sealable liner that creates a seal when heat is applied. The liner is typically made of materials like aluminum foil or coated paper, and it adheres to the container rim when heated, providing a secure seal.

6.Polyethylene (PE) Wadding Caps: These caps have a liner made of polyethylene, a flexible plastic material. PE wadding caps are commonly used for products like lotions, creams, or other non-liquid substances.

8.EPE (Expanded Polyethylene) Wadding Caps: EPE wadding caps have a liner made of expanded polyethylene foam. This type of liner offers cushioning and protection for fragile or delicate products. EPE wadding caps are often used for items like cosmetics, electronic components, or medical devices.

These are just a few examples of the different types of wadding caps available. The selection of the appropriate wadding cap depends on factors such as the type of product, the desired level of sealing, and specific packaging requirements.

Driving Innovation and Advancements:

As industries keep evolving, cap wadding machines continue to witness ongoing innovation and advancements. Manufacturers are continuously striving to develop machines that offer even higher speeds, improved precision, greater flexibility, and enhanced control mechanisms. Researchers and engineers are also exploring eco-friendly materials for wads, promoting sustainability and meeting the growing demand for environmentally conscious packaging solutions.

In Conclusion:

Cap wadding machines have revolutionized the manufacturing and packaging industries, providing efficient and precise wad insertion into caps or closures. Offering a range of advantages, such as efficiency, accuracy, versatility, and cost savings, these machines have become indispensable for organizations aiming to enhance productivity while maintaining product integrity. As technologies continue to progress, cap wadding machines will further drive innovation in the packaging sector, ensuring a seamless and reliable sealing process for a wide array of products.

Contact: iForcePack

Phone: +86-198 7511 8892

E-mail: info@iforcepack.com

Add: J101,Haitang,Siji huacheng, Bantian Street, Longgang District, Shenzhen, Guangdong, China