In today's fast-paced business environment, companies need to be efficient and productive to remain competitive. One area where companies can significantly improve efficiency is in product packaging and logistics. Labeling machines are an essential tool that companies can use to streamline labeling processes and improve productivity.

What is a labeling machine?

A labeling machine is a piece of equipment used to apply labels to products, packages, or containers. These machines come in various designs and can be used to apply different types of labels, such as self-adhesive labels, pressure-sensitive labels, and shrink-sleeve labels. A label printer can also be added to the machine to print variable information, such as batch numbers, expiry dates, and barcodes directly on the label.

How does a labeling machine work?

Labeling machines are designed to be easy to use and can be operated by just one person. They typically consist of a conveyor system that moves products or packages through the machine and a label applicator that applies the labels to the products or packages. The label applicator uses a variety of methods, such as a roller, a vacuum, or a piston, to apply the label precisely and accurately to the product or package.

Why use a labeling machine?

Using a labeling machine offers several benefits, including:

1.Increased efficiency and productivity

Labeling machines can significantly improve the efficiency and productivity of labeling processes. These machines can apply labels much faster and more accurately than manual labeling, reducing the time and labor required for labeling tasks.

2.Reduced errors and waste

Labeling machines are designed to apply labels precisely and accurately, which can reduce errors and waste. This ensures that products are labeled correctly and that no labels are wasted due to misapplication or damage.

3.Compliance with labeling regulations

Many industries have strict labeling regulations that companies must comply with. Labeling machines can help ensure that labels meet these regulations, reducing the risk of fines or other penalties for non-compliance.

4.Customization and flexibility

Labeling machines can be customized to meet the specific labeling needs of different products and packages. They can also be adjusted to apply different label types and sizes, making them a flexible tool for a wide range of labeling tasks.

What are the different types of labeling machines?

There are several different types of labeling machines, each designed for specific labeling tasks:

1.Wrap-around labeling machines: These machines are used to apply labels to cylindrical or round-shaped products, such as bottles or cans.

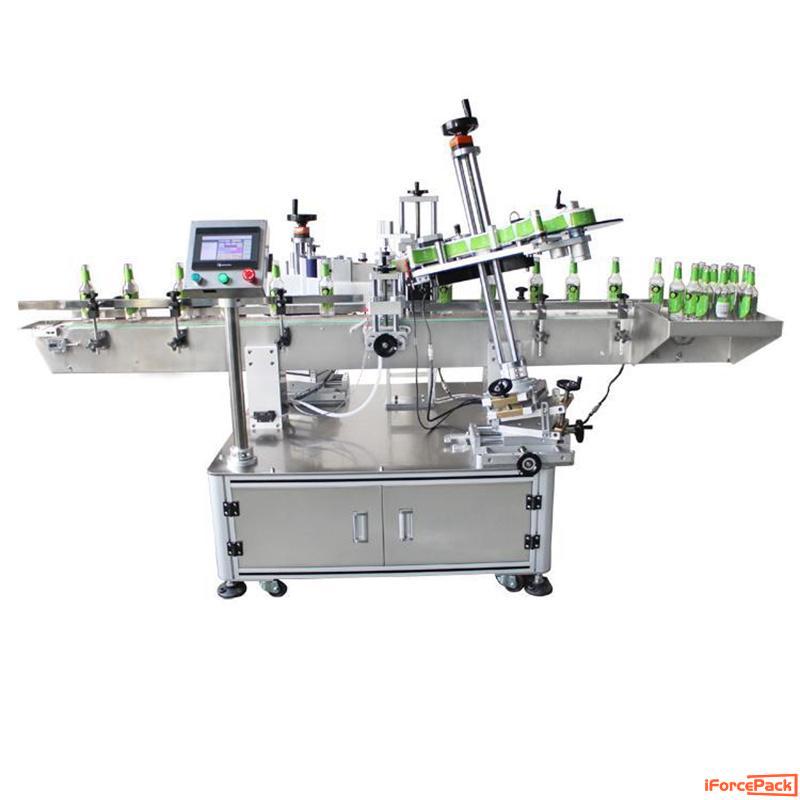

2.Front and back labeling machines: These machines are used to apply labels to the front and back of flat products, such as boxes or bags.

3.Top labeling machines: These machines are used to apply labels to the top of products, such as jars or bottles.

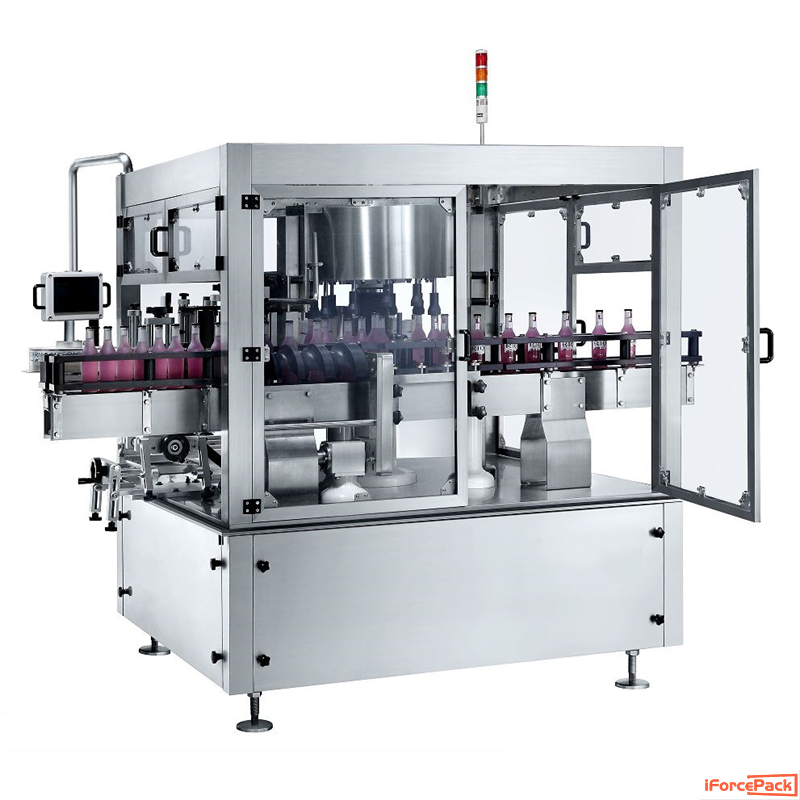

4.Sleeve labeling machines: These machines are used to apply shrink-sleeve labels to products, creating a 360-degree wrap-around label.

5.Print and apply labeling machines: These machines combine a label printer and a label applicator to print variable information on the label and apply it to the product.

Conclusion

Labeling machines are an essential tool for companies that want to improve the efficiency and productivity of their labeling processes. They offer several benefits, including increased efficiency and productivity, reduced errors and waste, compliance with labeling regulations, and customization and flexibility. With several different types of labeling machines available, companies can choose the machine that best meets their specific labeling needs.

Contact: iForcePack

Phone: +86-198 7511 8892

E-mail: info@iforcepack.com

Add: J101,Haitang,Siji huacheng, Bantian Street, Longgang District, Shenzhen, Guangdong, China