Traditional labeling equipment:Paper label cold wet glue labeling machine

In today's competitive market, product labeling plays a crucial role in attracting customers and communicating key information about the product. To ensure precise and efficient labeling, businesses often rely on advanced labeling machines. One such machine, the Cold Wet Glue Labeling Machine, has gained popularity for its ability to deliver accurate and high-quality label application. In this article, we will explore the features and benefits of the Cold Wet Glue Labeling Machine and understand why it is an essential tool for businesses.

A wet cold glue labeling machine, also known as a cold glue label applicator or a wet adhesive labeling machine, is a type of equipment specifically designed to apply wet cold glue labels onto containers, packages, or products. It is commonly used in industries such as beverage, food, pharmaceuticals, and cosmetics.

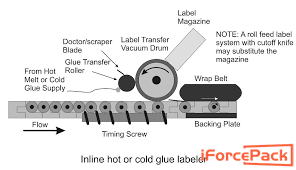

A wet cold glue labeling machine typically consists of the following components:

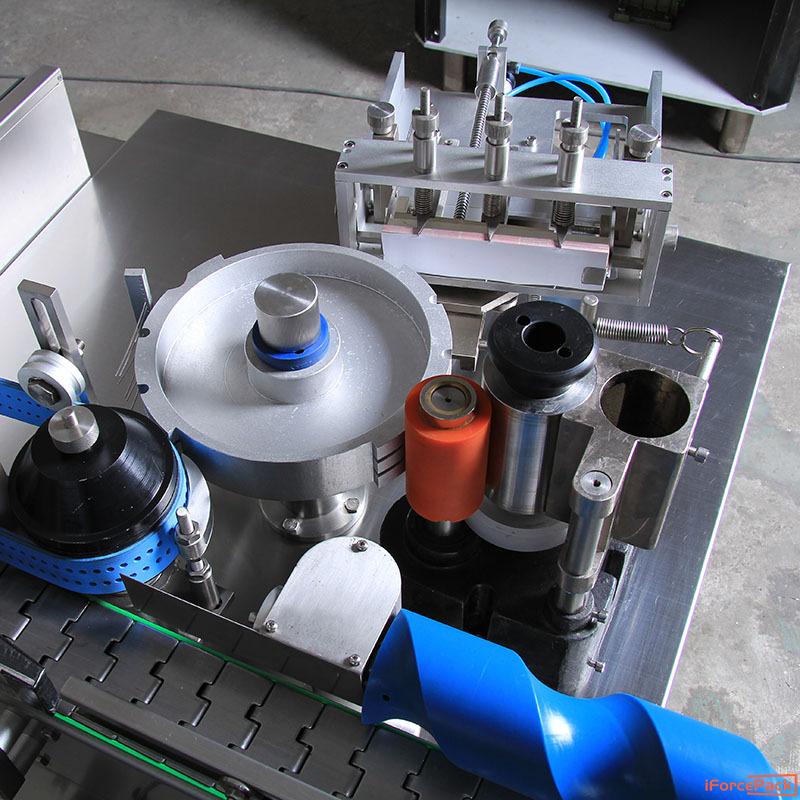

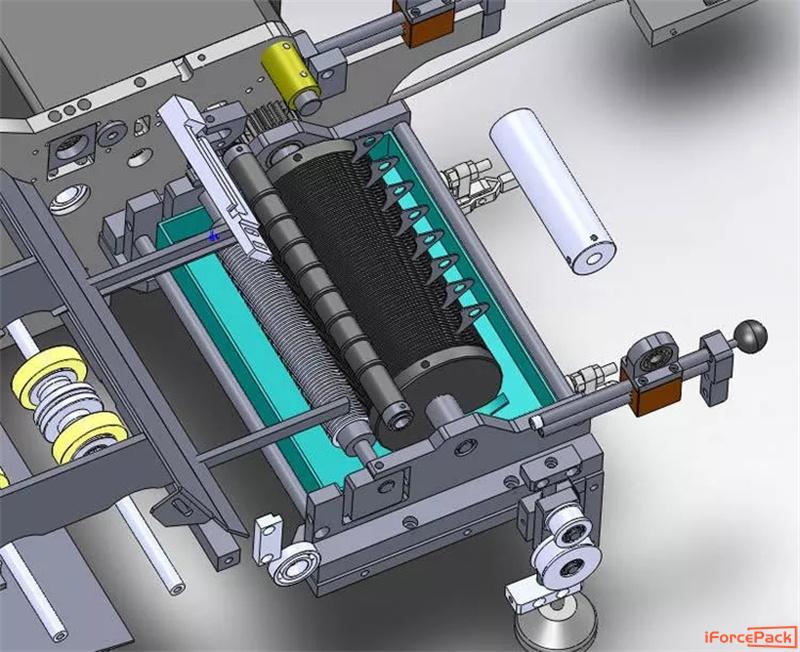

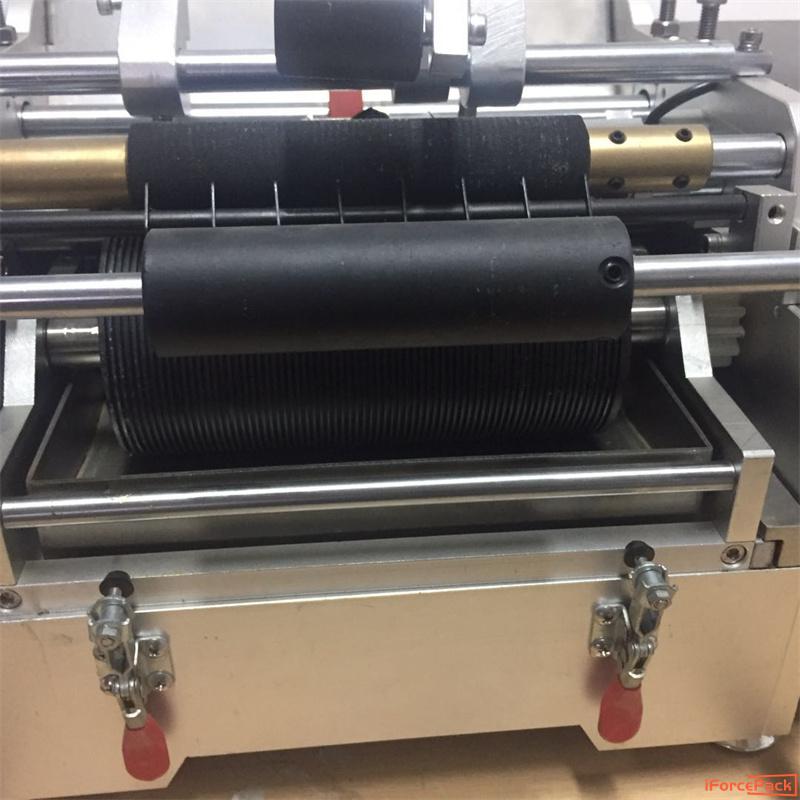

1.Labeling Head: This is the part of the machine that holds the label and applies the wet cold glue onto it. It may use rollers or brushes to ensure even distribution of the adhesive.

2.Glue Station: This is where the wet cold glue is stored and dispensed onto the labels. The glue is usually contained in a reservoir or a glue pot, and a mechanism ensures a consistent flow and spread of the adhesive.

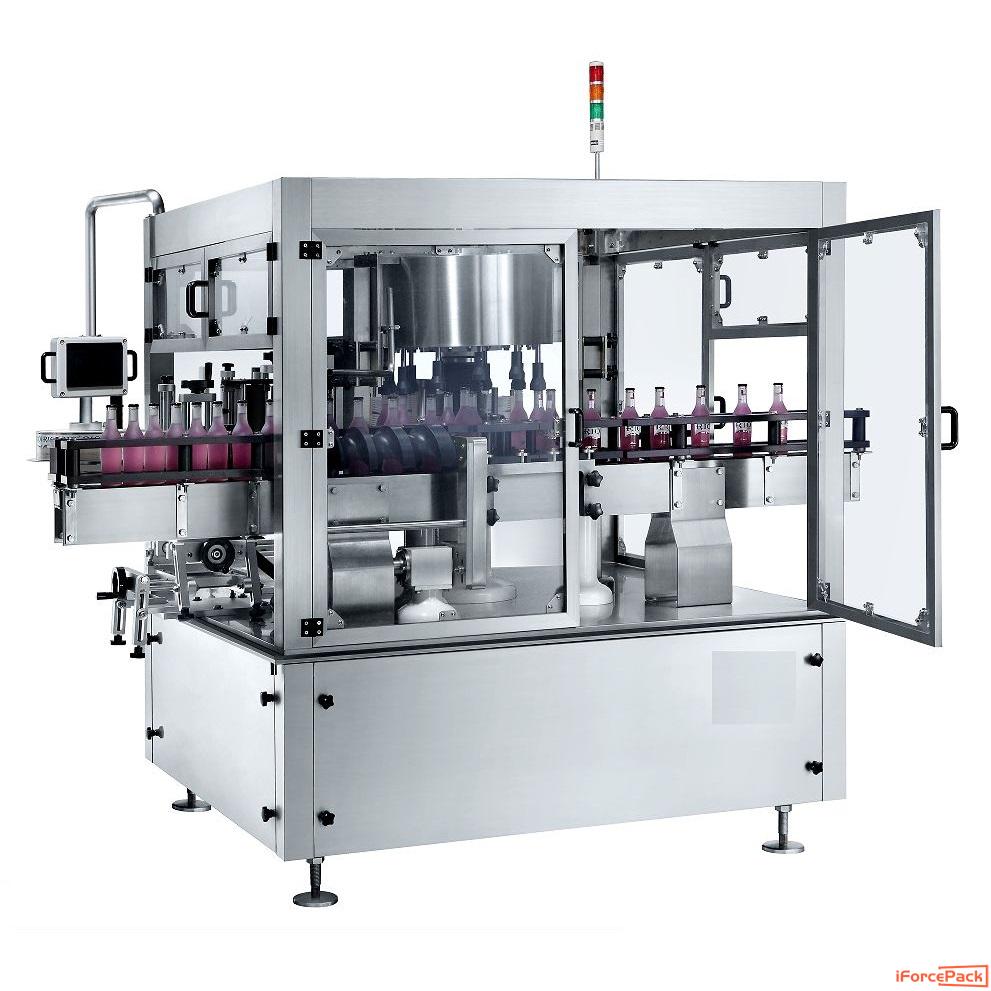

3.Container/Product Handling System: This part of the machine is responsible for conveying the containers or products through the labeling process. It may include conveyor belts, rotating platforms, or other mechanisms to ensure proper alignment and positioning for label application.

4.Control Panel: The labeling machine is typically equipped with a control panel that allows operators to set various parameters, such as label speed, label size, glue flow, and other settings.

The process of using a wet cold glue labeling machine involves the following steps:

1.Label Preparation: The labels, typically pre-cut or in roll form, are loaded onto the machine, ensuring they are properly aligned and ready for adhesive application.

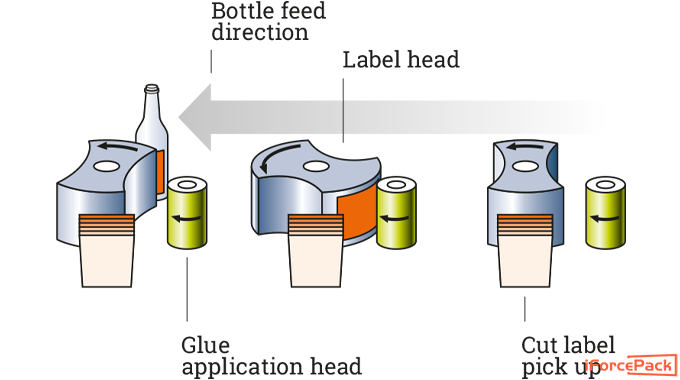

2.Glue Application: The wet cold glue is applied onto the labels as they pass through the labeling head. The glue is spread evenly, either by rollers or brushes, to ensure proper adhesive coverage.

3.Container/Product Placement: The containers or products to be labeled are introduced into the machine's handling system, which positions them correctly for label application.

4.Label Application: As the containers/products move through the machine, the labels are applied using rollers, brushes, or other mechanisms. The wet glue on the label adheres to the surface of the container/product, creating a secure bond as the glue dries or cures.

Some key features and benefits of desktop cold glue labeling machines include:

Accurate Label Application:

The Cold Wet Glue Labeling Machine is designed to ensure precise label application on various products. Unlike pressure-sensitive or self-adhesive labels, cold glue labels require an adhesive to be applied to the label itself before it is attached to the product. The machine precisely dispenses the water-based adhesive onto each label, ensuring consistency in the amount of glue applied. This guarantees accurate and uniform placement of the labels on the product, resulting in a professional and visually appealing appearance.

Versatility:

One of the key advantages of the Cold Wet Glue Labeling Machine is its versatility. It can handle a wide range of product shapes, sizes, and materials, making it suitable for various industries such as food and beverage, cosmetics, pharmaceuticals, and more. Whether you need to label bottles, jars, cans, or other containers, this machine provides a reliable and efficient solution.

Improved Durability and Adhesion:

Cold glue labels offer enhanced durability and adhesion compared to other labeling methods. The water-based glue used in cold glue labels forms a strong bond with the product's surface, ensuring long-lasting adhesion. This is particularly beneficial for products that may be exposed to moisture, heat, or rough handling. The Cold Wet Glue Labeling Machine ensures proper adhesion, reducing the risk of labels peeling or becoming damaged during transportation or use.

Cost-Effective Solution:

Utilizing cold glue labels with a Cold Wet Glue Labeling Machine offers a cost-effective labeling solution for businesses. Cold glue labels are generally more affordable than pressure-sensitive or self-adhesive labels. Additionally, the water-based adhesive used in cold glue labels is less expensive compared to other adhesive options. This makes the Cold Wet Glue Labeling Machine a cost-efficient choice for businesses looking to maximize their labeling budget without compromising quality.

Ease of Maintenance:

Cold Wet Glue Labeling Machines are known for their ease of maintenance. They are built with user-friendly designs that allow for easy cleaning and maintenance operations. The machine's components are easily accessible, ensuring quick and hassle-free repairs or replacements if needed. This reduces downtime and ensures optimal performance of the machine, keeping your labeling operations running smoothly.

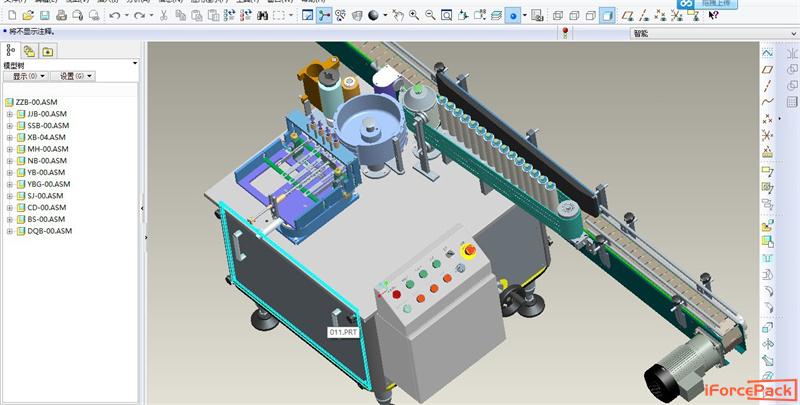

There are several types of Cold Wet Glue Labeling Machines available in the market. The type of machine required depends on the specific needs of the business, such as the product shape, size, and labeling requirements. Here are a few common types of Cold Wet Glue Labeling Machines:

1.Rotary Cold Wet Glue Labeling Machine: This type of machine operates in a rotary system, allowing for high-speed labeling. It is suitable for labeling multiple items simultaneously on a rotating platform, making it ideal for industries that require mass production.

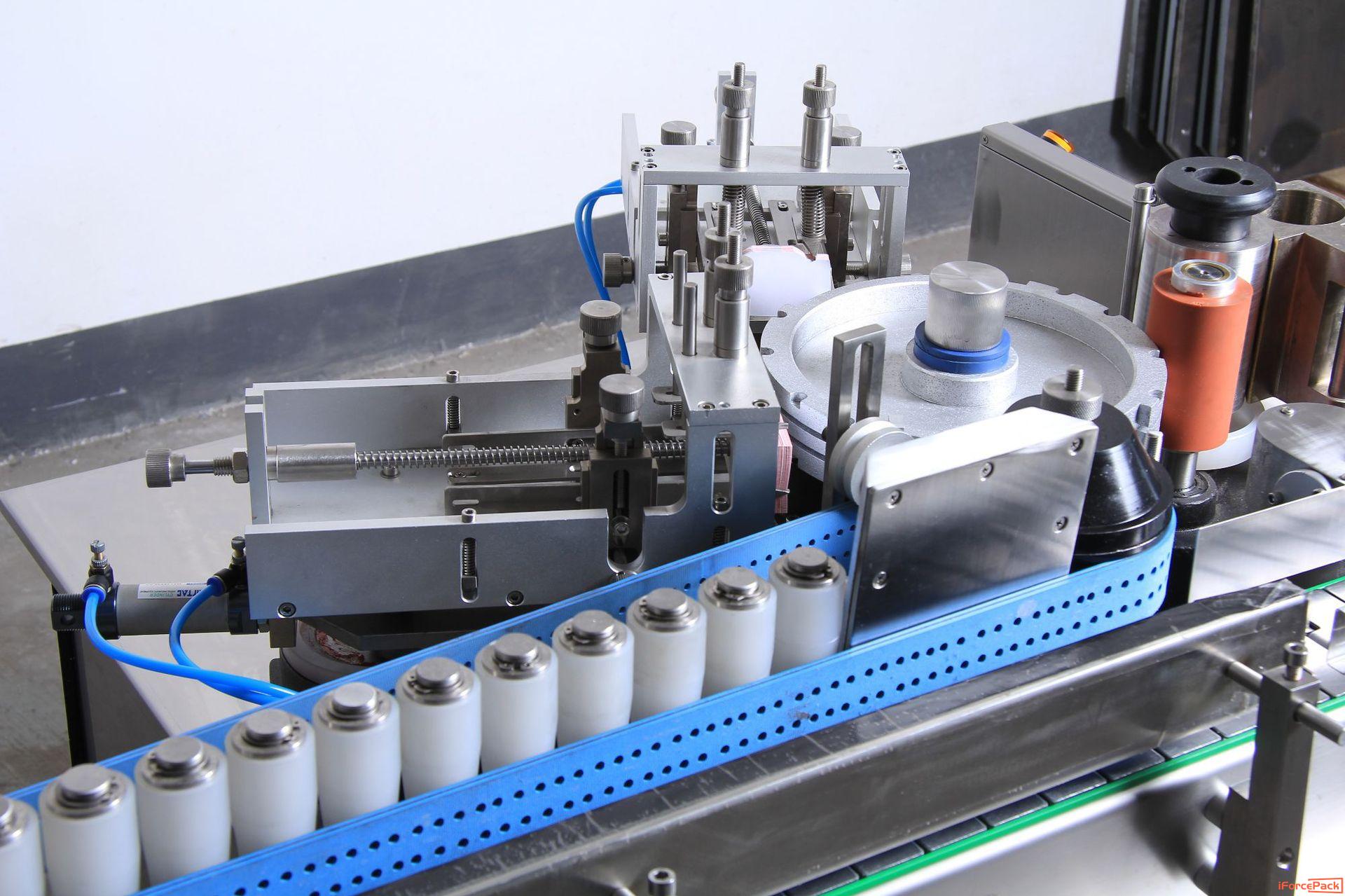

2.Linear Cold Wet Glue Labeling Machine: This machine functions in a linear or straight-line manner, making it suitable for smaller or irregularly shaped products. It offers precise labeling at a lower speed, making it ideal for industries with diverse packaging requirements.

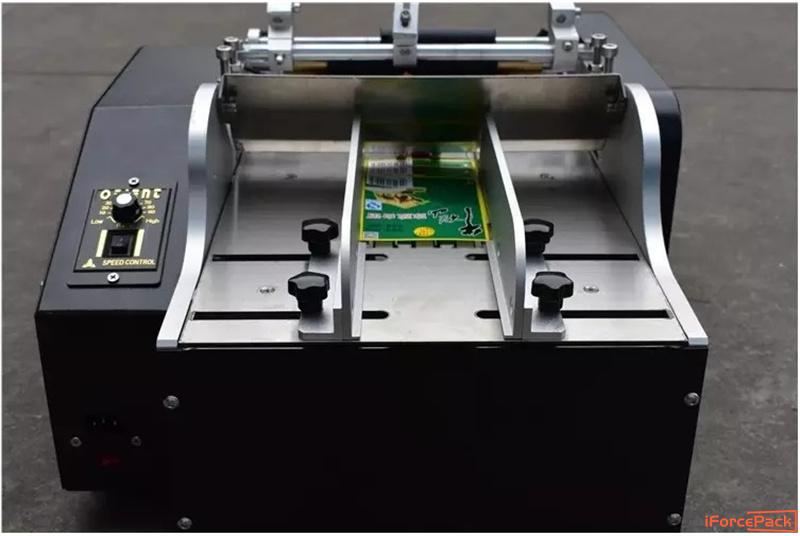

3.Desktop cold wet glue labeling machine

A desktop cold glue labeling machine, also known as a tabletop cold glue labeler, is a compact and versatile machine designed for applying cold glue labels to various products. It is typically used in small-scale production settings where space is limited.

The desktop cold glue labeling machine operates by dispensing a water-based adhesive onto labels, which are then applied to products as they pass through the machine. The labels are precisely positioned and pressed onto the products for optimal adhesion.

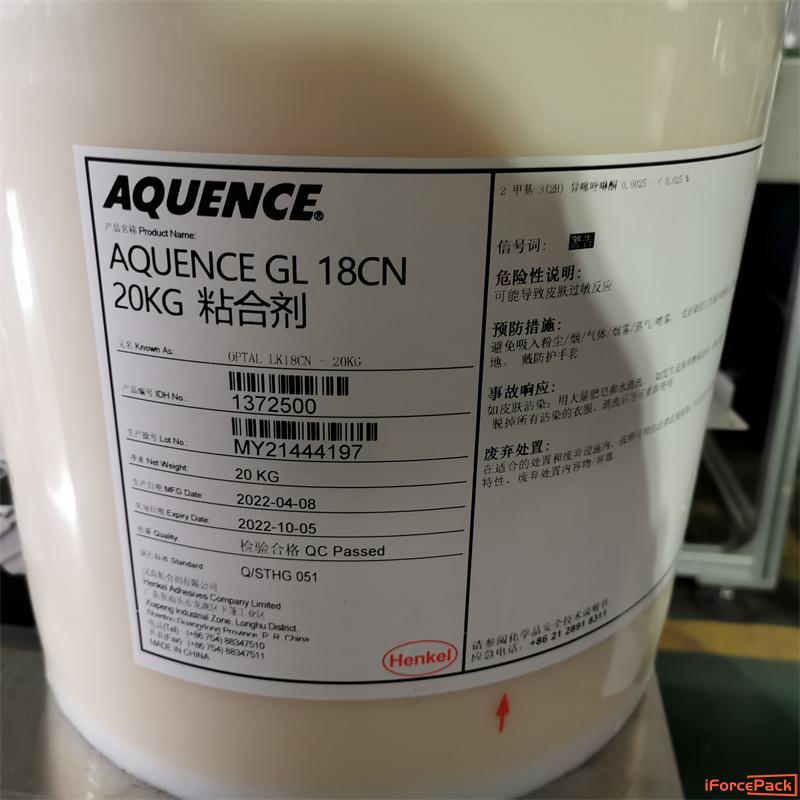

What is wet cold glue?

Wet cold glue, also known as cold glue or wet adhesive, refers to a type of glue or adhesive that is typically used in labeling applications. It is called "cold" glue because it does not require heat or any special equipment to activate or apply it. Instead, it is applied in a liquid form and then dries or cures through exposure to air.

Wet cold glue is commonly used in labeling machines for applying paper labels onto various products such as bottles, jars, or cans. The glue is typically water-based and has a low viscosity, allowing it to spread evenly on the label and adhere to the surface of the product.

The process of applying wet cold glue labels involves the application of a thin layer of glue onto the label, either by roller or brush. The labeled product is then passed through a glue station on the labeling machine where the glue-coated label is applied to the product. The wet glue on the label adheres to the surface of the product, forming a strong bond as it dries.

Wet cold glue offers several advantages in labeling applications. It provides excellent adhesion on a wide range of surfaces, including glass, plastic, metal, and paper. It also allows for easy label repositioning during the labeling process, making it flexible and suitable for various label sizes and shapes.

Application of Cold Glue Labels:

The application of cold glue labels involves the use of cold glue labeling machines. These machines dispense the water-based adhesive onto the labels, either through multiple glue rollers or via precise nozzle systems. The labeled products then pass through a glue station where the labels are applied with pressure or rollers, ensuring proper adhesion.

Cold glue labeling machines are available in different configurations, including rotary and linear types, to meet specific production requirements and label sizes. They can handle high-speed operations for mass production or slower speeds for specialized labeling applications.

Conclusion:

The Cold Wet Glue Labeling Machine offers businesses a reliable and efficient labeling solution. Its accuracy in label application, versatility, improved durability and adhesion, cost-effectiveness, and ease of maintenance make it an indispensable tool for various industries. By investing in a Cold Wet Glue Labeling Machine, businesses can streamline their labeling process, enhance product presentation, and gain a competitive edge in the market.

Contact: iForcePack

Phone: +86-198 7511 8892

E-mail: info@iforcepack.com

Add: J101,Haitang,Siji huacheng, Bantian Street, Longgang District, Shenzhen, Guangdong, China