A capping machine is a type of industrial equipment that is used to apply caps or closures onto containers such as bottles, jars, or tubes. Capping machines can be used for a variety of products such as food, beverages, pharmaceuticals, and cosmetics.

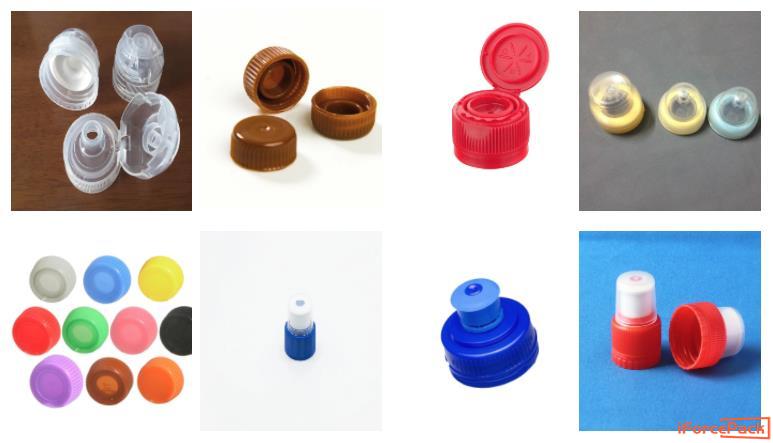

There are different types of capping machines available, each with their own unique capabilities and specifications. For example, some capping machines are designed to handle only certain types of caps or containers, while others are more versatile and can handle a wider range of sizes and shapes. Additionally, capping machines can be designed to work with different types of caps such as screw caps, snap caps, or crimped caps.

Types of Capping Machines:

There are several types of capping machines, each with their unique specifications and capabilities. The most common types of capping machines include:

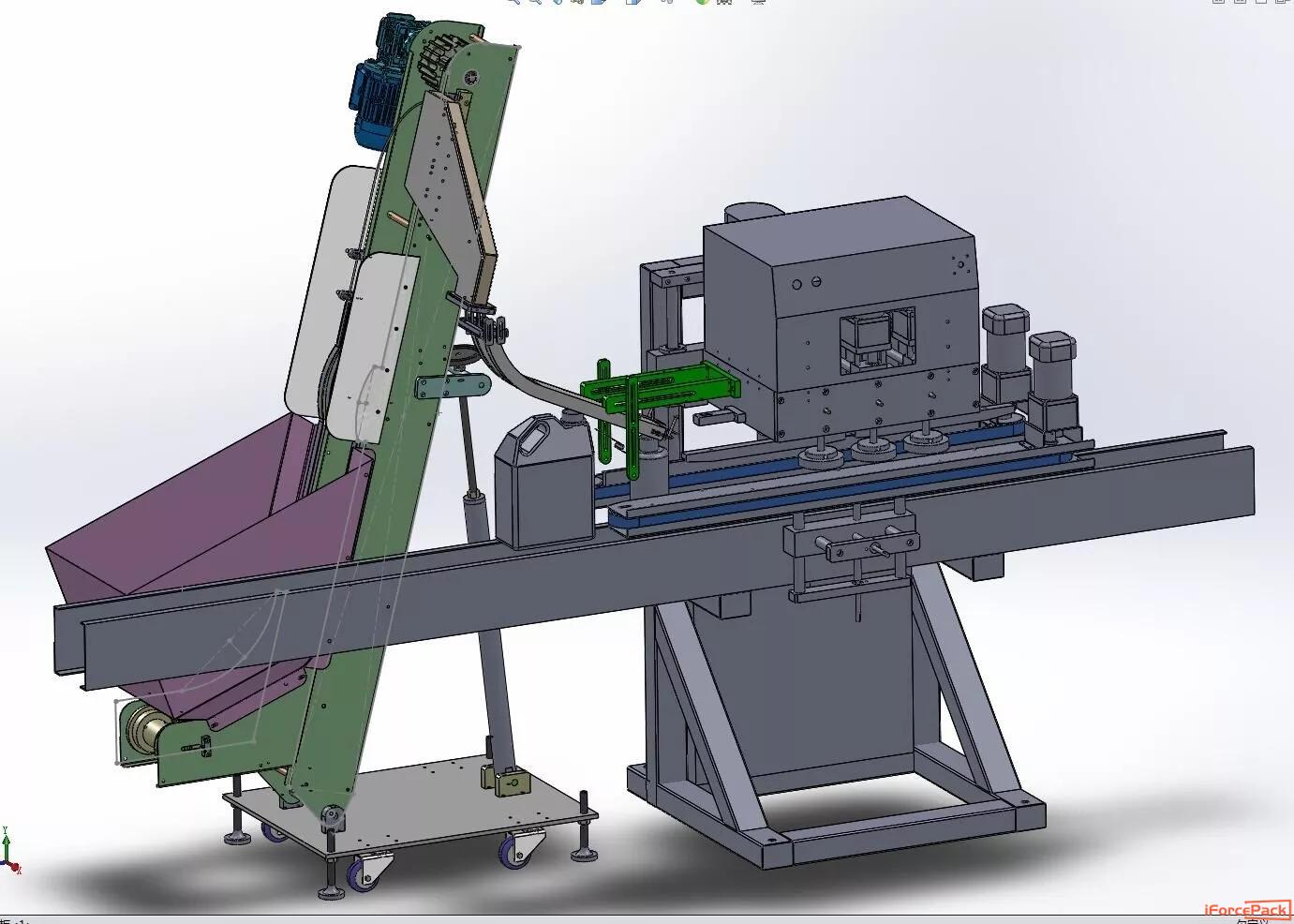

1.Automatic Capping Machines:

As the name suggests, automatic capping machines can automatically cap a large number of containers at high speed, making them ideal for industries that require a high level of production. These machines are capable of handling different types of caps such as screw caps, snap caps, and crimped caps.

2.Semi-Automatic Capping Machines:

Semi-automatic capping machines require human intervention to load and unload containers, but they are capable of capping different types of caps onto containers. These machines are suitable for industries that require lower production rates and are also more cost-effective compared to automatic capping machines.

3.Manual Capping Machines:

Manual capping machines are the simplest type of capping machines and require manual labor to cap containers. These machines are suitable for small-scale production and are often used in laboratories or research facilities.

Features of Capping Machines:

Capping machines can have various features that enhance their functionality and performance. Some machines come with cap feeders that automatically supply caps to the capping head, while others have a cap elevator that lifts and supplies caps to the machine. Additionally, capping machines can be equipped with torque sensors that ensure the caps are tightened to the correct torque, preventing leaks and product contamination.

Importance of Capping Machines in the Food and Beverage Industry:

In the food and beverage industry, capping machines play a crucial role in ensuring the safety and quality of the product. The tight seal provided by capping machines prevents contamination and extends the shelf life of the product. Additionally, capping machines in the beverage industry can be designed to handle carbonated beverages, ensuring that the caps are applied without affecting the carbonation levels.

Importance of Capping Machines in the Pharmaceutical Industry:

In the pharmaceutical industry, capping machines are used to ensure the safety and efficacy of the product. The tight seal provided by capping machines prevents air and moisture from entering the container, which can affect the potency of the product. Additionally, capping machines can handle different types of caps, including child-resistant caps, which are required for certain types of medications.

The global capping machine market size was valued at USD 5.5 billion in 2020 and is expected to reach USD 7.3 billion by 2026, growing at a CAGR of 4.5% during the forecast period (2021-2026).

Automatic capping machines accounted for the largest market share in 2020, and this trend is expected to continue during the forecast period.

The food and beverage industry is the largest end-user of capping machines, accounting for the largest market share in 2020. The pharmaceutical and cosmetics industries are also significant end-users.

North America accounted for the largest market share in 2020, followed by Europe and Asia-Pacific.

The increasing demand for packaged food and beverages, the growing pharmaceutical and cosmetics industries, and the need for efficient and reliable packaging solutions are some of the key factors driving the growth of the capping machine market.

The global capping machine market size was valued at USD 5.5 billion in 2020 and is expected to reach USD 7.3 billion by 2026, growing at a CAGR of 4.5% during the forecast period (2021-2026).

Automatic capping machines accounted for the largest market share in 2020, and this trend is expected to continue during the forecast period.

The food and beverage industry is the largest end-user of capping machines, accounting for the largest market share in 2020. The pharmaceutical and cosmetics industries are also significant end-users.

North America accounted for the largest market share in 2020, followed by Europe and Asia-Pacific.

The increasing demand for packaged food and beverages, the growing pharmaceutical and cosmetics industries, and the need for efficient and reliable packaging solutions are some of the key factors driving the growth of the capping machine market.

Conclusion:

In conclusion, capping machines are an integral part of many industries that require efficient and consistent capping of containers. The different types of capping machines cater to different production rates and cap types, making them versatile equipment. Overall, capping machines play a critical role in ensuring the quality and safety of the product, while also improving production efficiency.

Contact: iForcePack

Phone: +86-198 7511 8892

E-mail: info@iforcepack.com

Add: J101,Haitang,Siji huacheng, Bantian Street, Longgang District, Shenzhen, Guangdong, China