Model:IF-C120

Power supply:Three phase 220/380V 50/60Hz

Production capacity:40-60 boxes/minute

Box:Quality requirement:300-400g/㎡(Base on carton size)

Compressed air:Working pressure:≥0.6Mpa

Air consumption:20L/Hour

Power:1.5kw

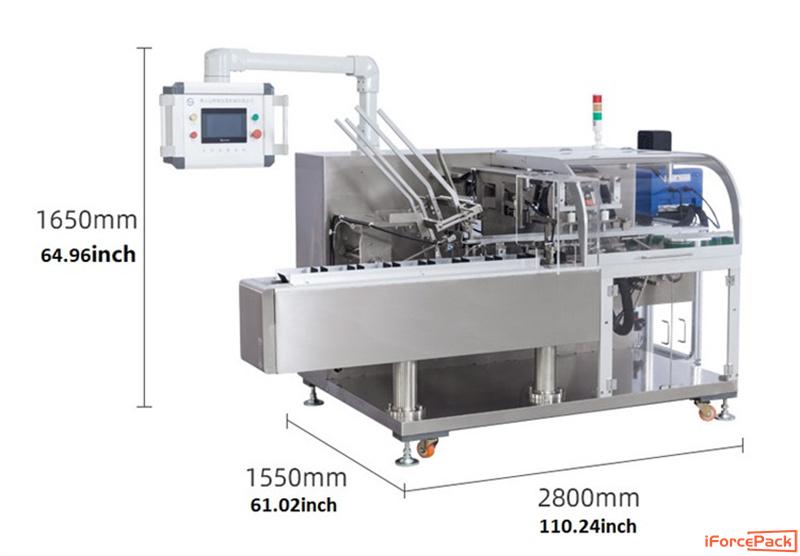

Machine dimension:2800 X 1550 X 1650mm

Machine weight:About 1300kg

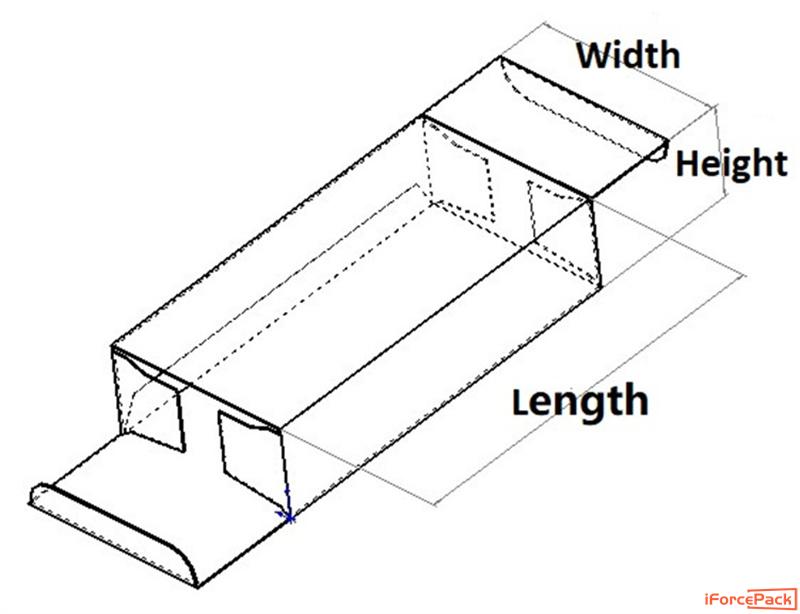

Box application range:

Max box size: L220mm*W165*H110mm(L8.66inch*W6.50inch*H4.33inch)

Min box size:L50mm*W25mm*H15mm.(L1.97inch*W0.98inch*0.59inch)

Automatic horizontal type hot melt glue cartoning machine

Model:IF-C120

Power supply:Three phase 220/380V 50/60Hz

Production capacity:40-60 boxes/minute

Box:Quality requirement:300-400g/㎡(Base on carton size)

Compressed air:Working pressure:≥0.6Mpa

Air consumption:20L/Hour

Power:1.5kw

Machine dimension:2800 X 1550 X 1650mm

Machine weight:About 1300kg

Box application range:

Max box size: L220mm*W165*H110mm(L8.66inch*W6.50inch*H4.33inch)

Min box size:L50mm*W25mm*H15mm.(L1.97inch*W0.98inch*0.59inch)

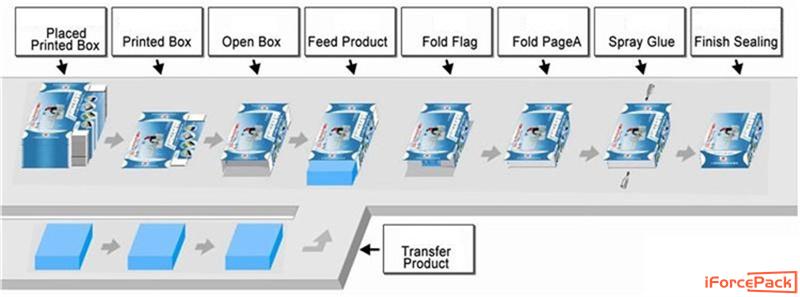

Machine working flow chart:

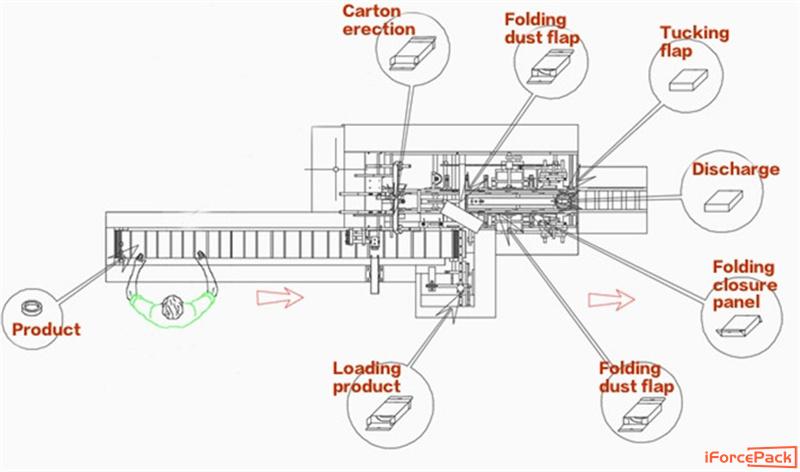

The relevant parts work instructions

1, The box frame mechanism

The cassette holder is used for stacking the position of the paper tray, and 200 to 300 paper trays can be placed at one time. When the paper tray is used up, the paper tray needs to be manually added, and the paper tray holder can be adjusted according to the size of the paper tray. Box holder adds spiral adjustment

If the mechanism is not adjusted (including the carton guide rails, suction cups) and the carton indentation is not deep, it will not open the box.

(The carton indentation is generally above 0.4MM depth, and the carton needs to have a pre-folding effect)

2, Product conveyor belt

The material conveyor belt is used to place the product. The conveyor belt can be adjusted according to the size of the product: the two screws can be loosened to move and the material can be adjusted.

Push the baffles on both sides of the grid to prevent the product from being released

3.Feeding port mechanism

Self-test protection system:

1) When sensing the product on the conveyor belt, the machine will automatically suck the box and push the material, otherwise it will not suck the box;

2) If there is product delivery, but there is no paper box on the box, the machine will automatically stop and play a self-detection function.

3) When the carton is sent to the pusher opening, there will be four upper baffles (up, down, left, and right) to open the box, so that the product can be pushed into the carton smoothly. If the product does not push in, the machine It will automatically stop and protect the machine and products.

The product and the outer box (length / width / height) need to have a gap of 2-3mm, in case the outer box is too small when pushing the material, can not push in and knock the carton.

Protective cover:

4, Sealing mechanism (Hot melt type)

When the product is loaded into the carton, the machine automatically folds the ears and folds on both sides (as shown).

This position is the specific part that adjusts the length/width/height of the machine. If you need to change the box of another size, this position needs to be adjusted accurately.

This mechanism is equipped with a protective glass cover to prevent sudden impact of other substances and affect the stability of the machine.

Hot melt glue tank:

Machine dimension:

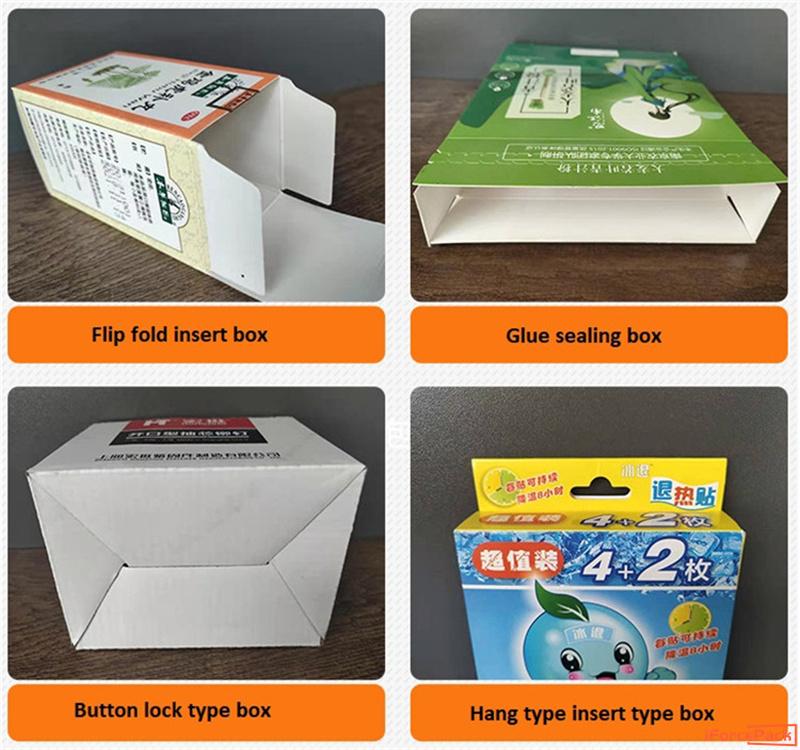

Sample box and box type:

Contact: iForcePack

Phone: +86-198 7511 8892

E-mail: info@iforcepack.com

Add: J101,Haitang,Siji huacheng, Bantian Street, Longgang District, Shenzhen, Guangdong, China