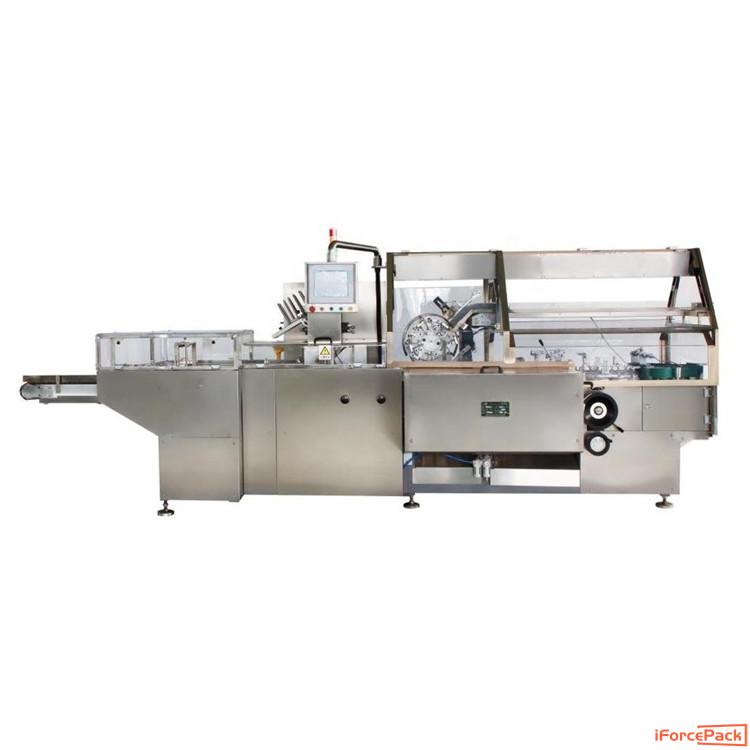

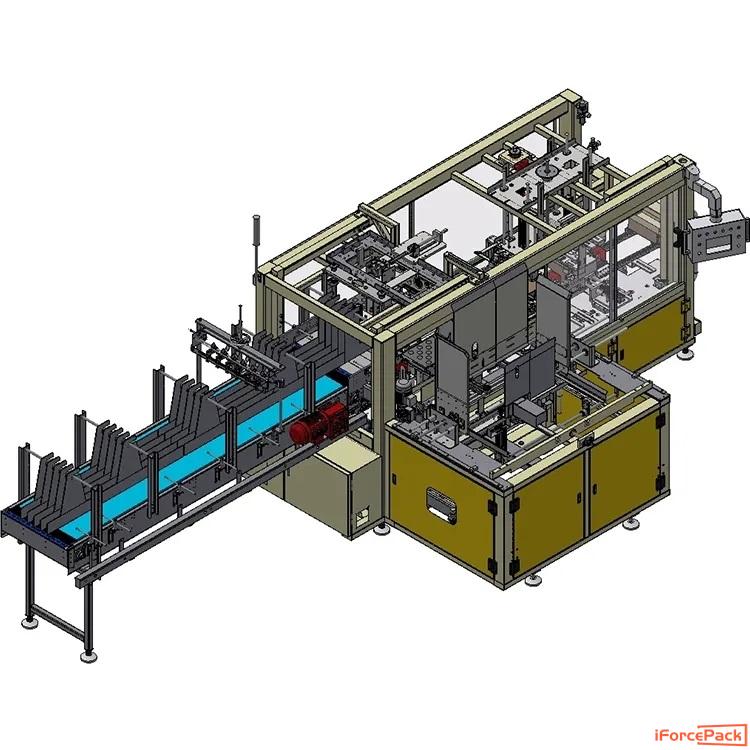

A cartoning machine is a type of packaging machinery used in the packaging industry to package products into cartons or boxes. These machines are used to automate the process of packaging products, and they can be found in a variety of industries, including food and beverage, pharmaceutical, and cosmetics.

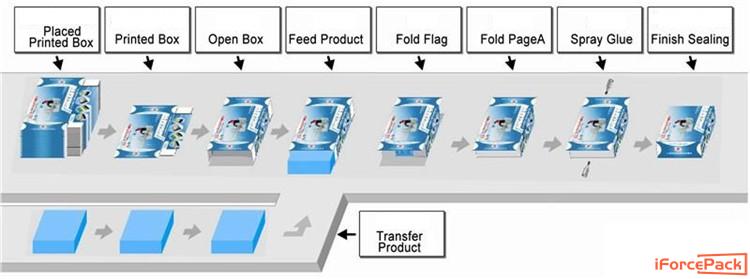

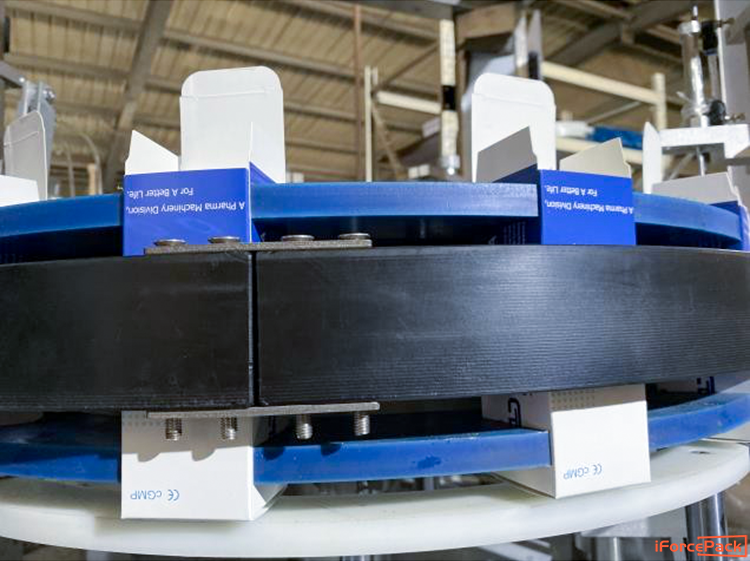

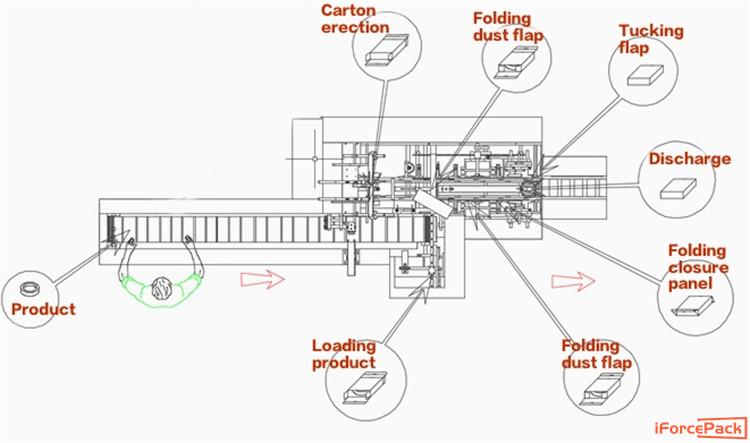

The primary function of a cartoning machine is to form, fill, and seal cartons or boxes. These machines come in different sizes and types, depending on the requirements of the product being packaged. Cartoning machines can be classified into two categories: horizontal and vertical cartoning machines.

1.Horizontal cartoning machines are used to package products that are flat or have a low height-to-width ratio. These machines are suitable for products like cereal boxes, chocolate bars, and frozen food products. Horizontal cartoning machines typically have a product loading area where the products are loaded into the carton. The carton is then closed by the machine.

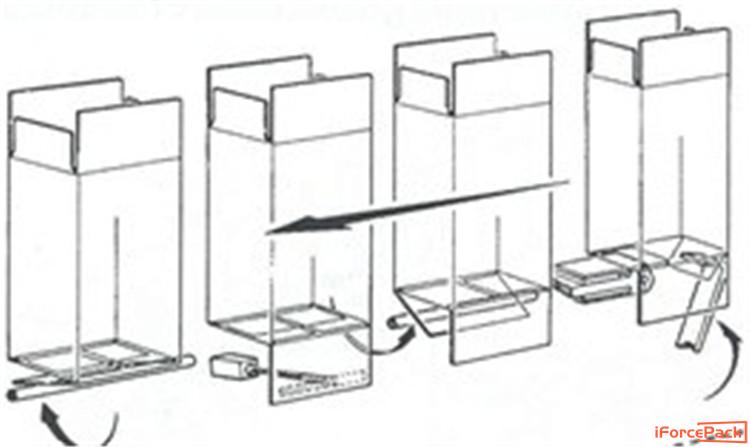

2.Vertical cartoning machines are used to package products that are taller than they are wide. These machines are suitable for products like bottles, tubes, and vials. Vertical cartoning machines typically have a product loading area where the products are loaded into the carton. The carton is then closed by the machine.

Cartoning machines can be further classified into three types based on the type of carton they can handle: end-load cartoning machines, side-load cartoning machines, and wrap-around cartoning machines.

1.End-load cartoning machines are used to package products that are loaded into the carton from the end. These machines are suitable for products like blister packs and bottles. The carton is then closed by the machine.

2.Side-load cartoning machines are used to package products that are loaded into the carton from the side. These machines are suitable for products like pouches and sachets. The carton is then closed by the machine.

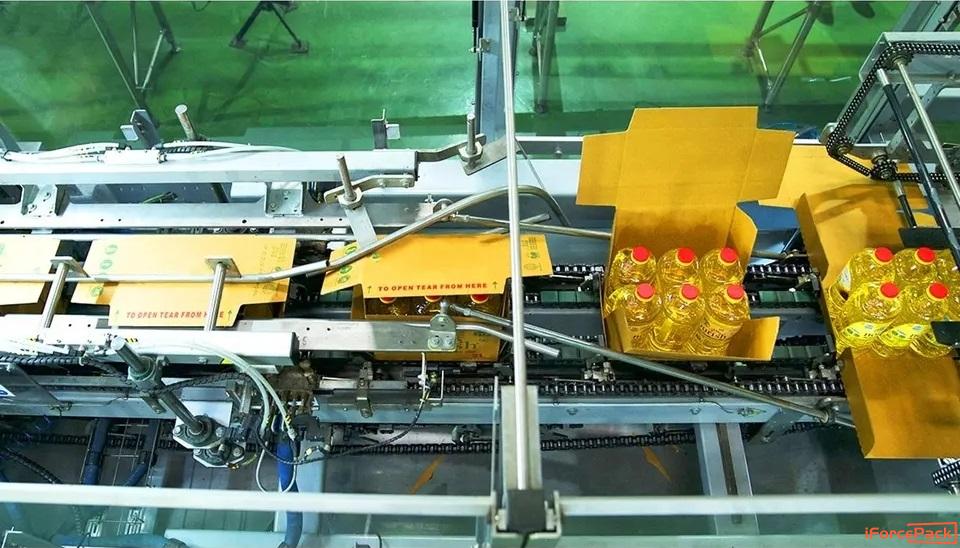

3.Wrap-around cartoning machines are used to package products that are wrapped around with a carton. These machines are suitable for products like bottles and cans. The carton is then closed by the machine.

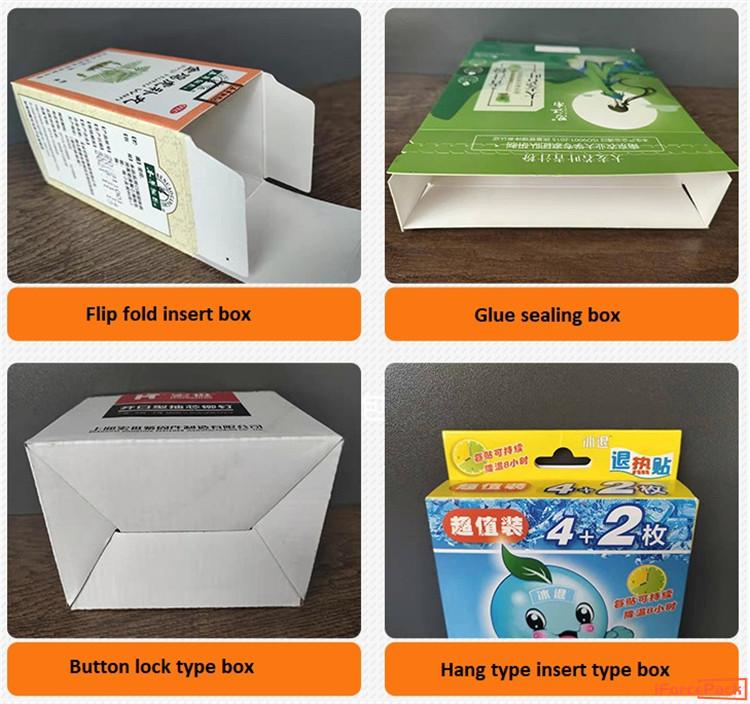

Cartoning machines can be further classified into two types based on the way they seal the carton: glue cartoning machines and tuck cartoning machines.

1.Glue cartoning machines are used to seal the carton with glue. These machines are suitable for products that require a strong seal, like glass bottles and jars. The carton is then closed by the machine.

2.Tuck cartoning machines are used to seal the carton with tuck flaps. These machines are suitable for products that require a less strong seal, like plastic bottles and pouches. The carton is then closed by the machine.

In conclusion, cartoning machines are an essential part of the packaging industry. They are used to automate the process of packaging products into cartons or boxes. There are different types of cartoning machines available in the market, each with its unique features and capabilities. When selecting a cartoning machine, it is essential to consider the type of product being packaged, the type of carton, and the seal type required.

Contact: iForcePack

Phone: +86-198 7511 8892

E-mail: info@iforcepack.com

Add: J101,Haitang,Siji huacheng, Bantian Street, Longgang District, Shenzhen, Guangdong, China