What is Bag-in-Box (BIB) Filling Machine?

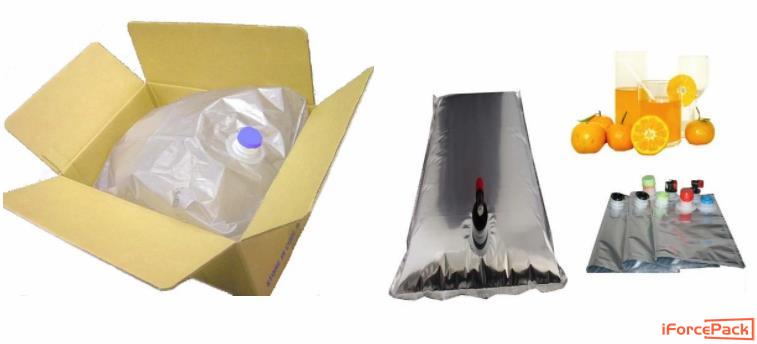

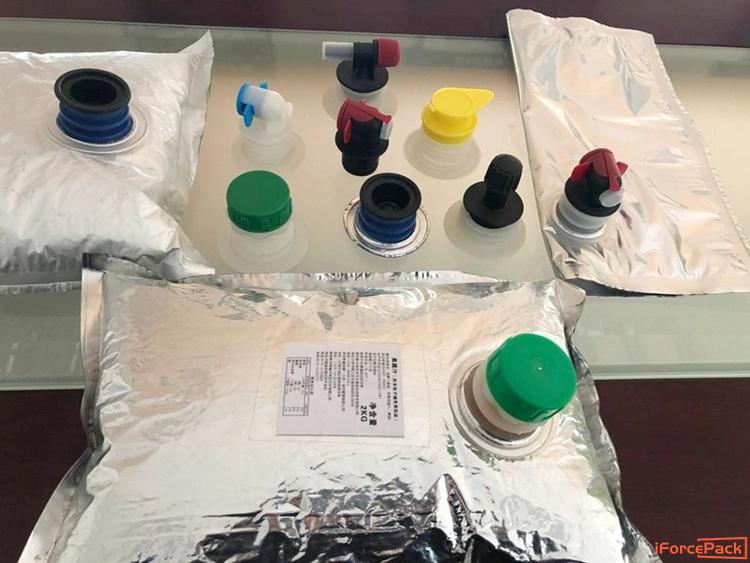

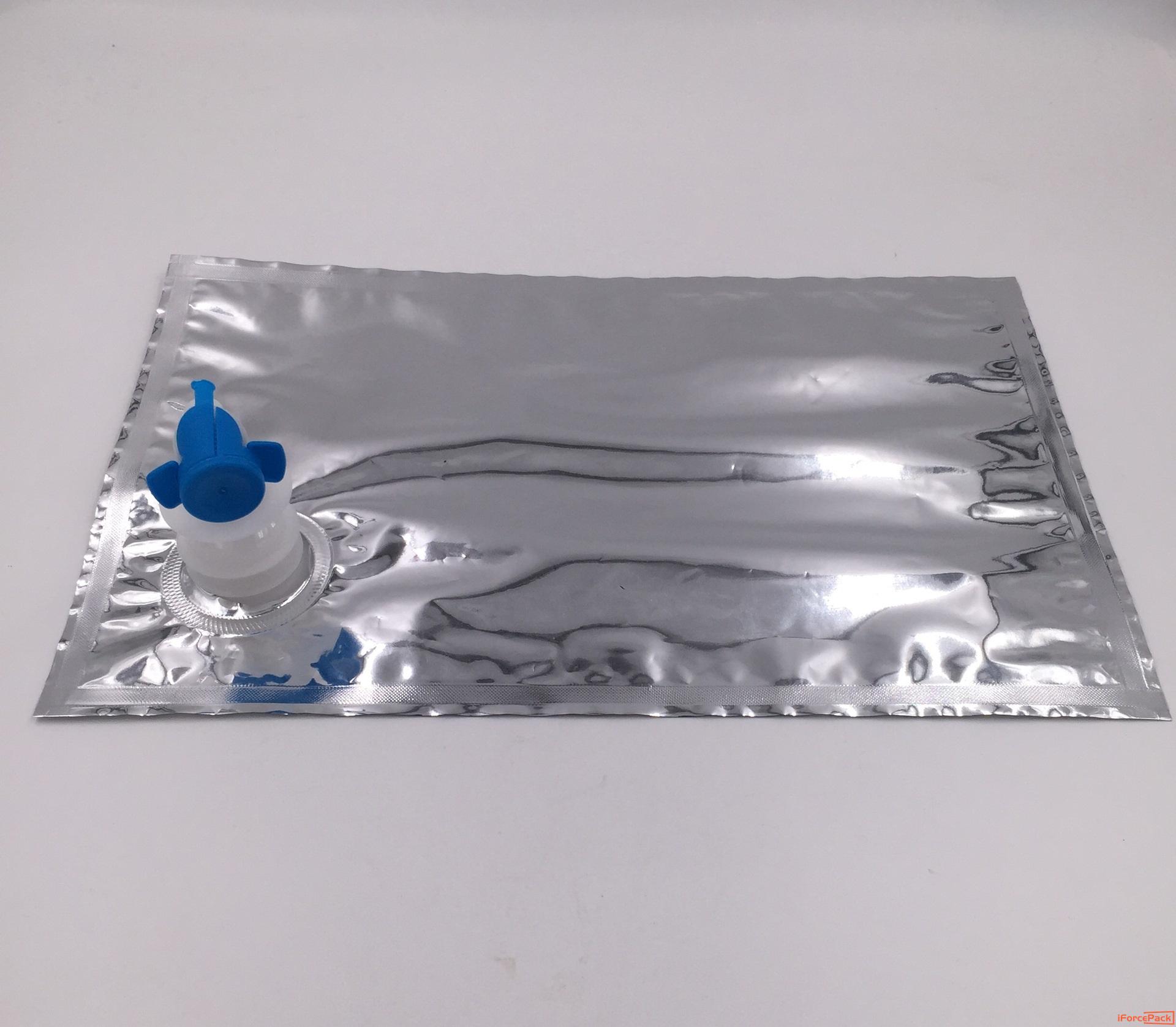

A BIB filling machine, also known as a Bag-in-Box filling machine, is a specialized piece of equipment used for filling liquid products into Bag-in-Box (BIB) bags. BIB packaging consists of a collapsible bag made of flexible material, typically plastic or metallized film, enclosed within a rigid outer box or carton. The BIB bag is equipped with a tap or valve that allows for easy dispensing of the product.

The BIB filling machine is designed to automate the filling process, ensuring efficiency, accuracy, and proper sealing of the bags. It is commonly used in industries such as food and beverage, dairy, wine, industrial liquids, and more. The machine operates based on specific principles and functionalities to handle the various stages of the filling process.

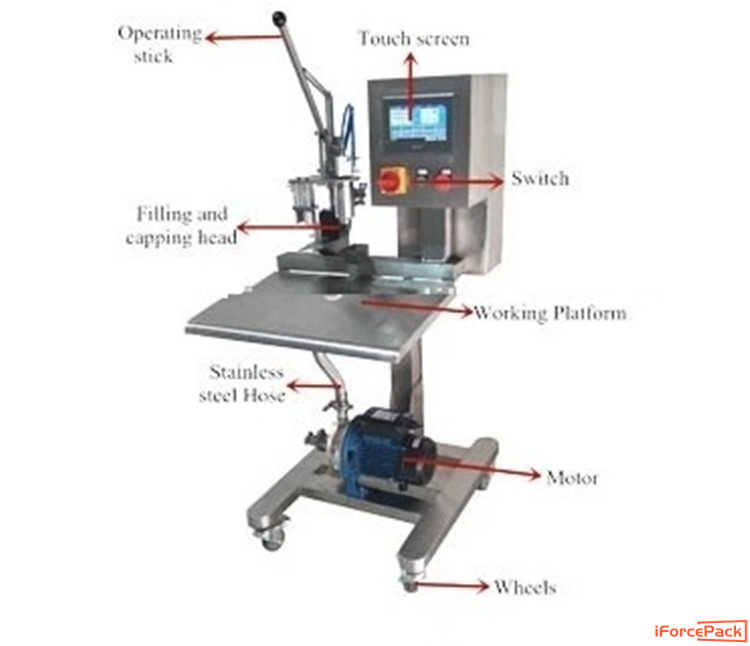

Key components and functionalities of a BIB filling machine include:

1.Bag Opening: The machine opens the BIB bag to prepare it for filling. This can be done through mechanisms such as mechanical clamps or suction devices that hold and stretch the bag's opening.

2.Product Supply System: The liquid product is supplied to the filling machine through a product supply system. This system can include pumps, gravity feed mechanisms, or other means of transferring the liquid from a storage tank or source to the filling machine.

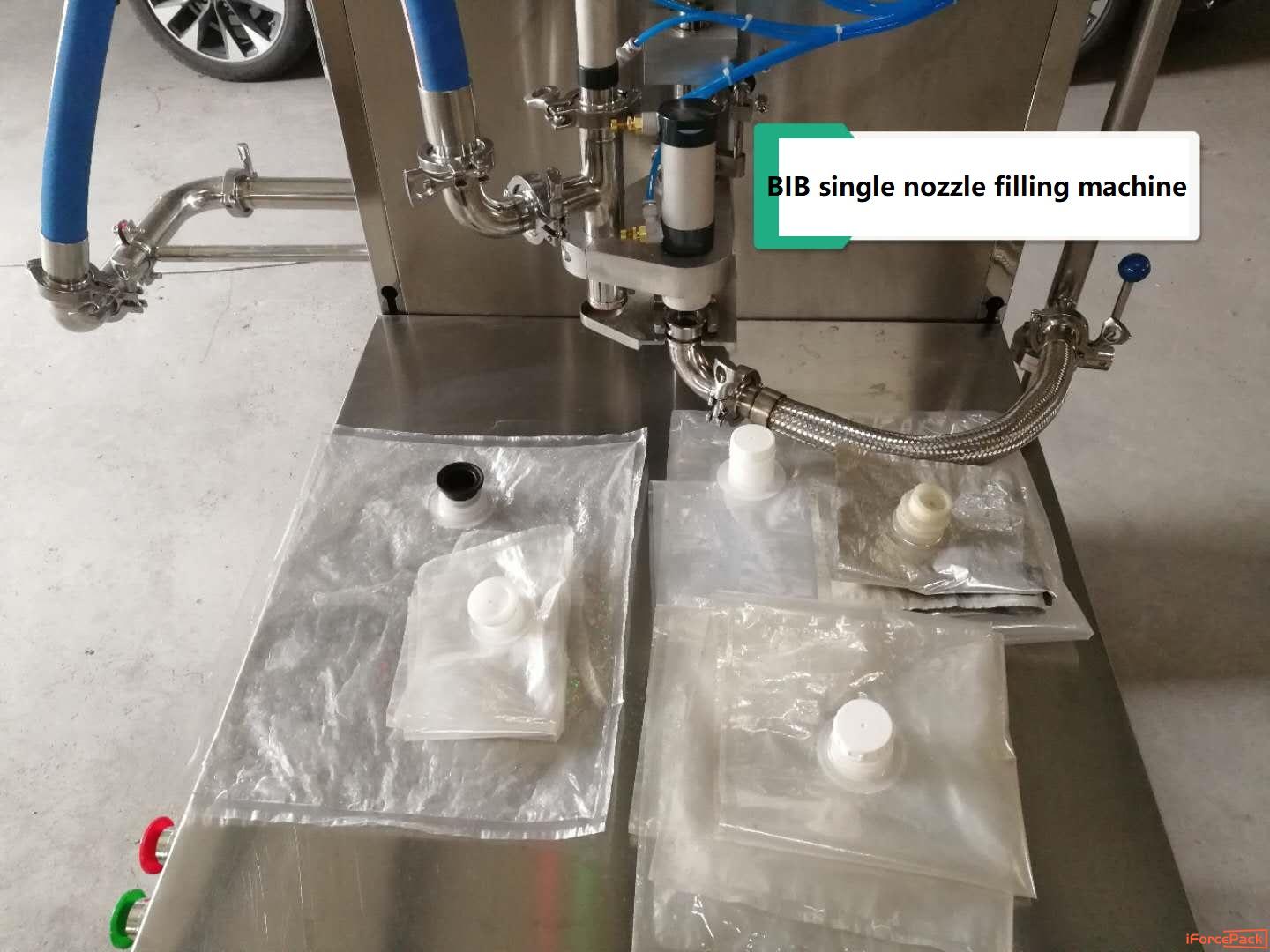

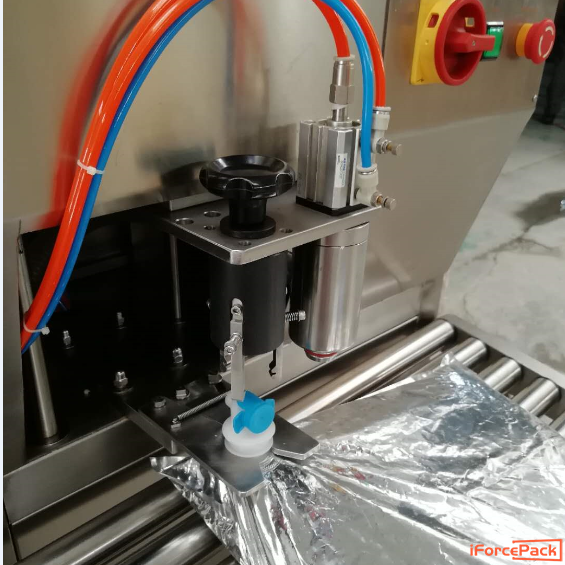

3.Filling Nozzle: The filling nozzle is a crucial component that connects to the product supply system and is inserted into the BIB bag's tap or valve. It ensures controlled and precise filling of the bag with the liquid product.

4.Volume Control: BIB filling machines are equipped with mechanisms to control the volume of the liquid being dispensed into each bag. This ensures accurate and consistent filling, preventing overfilling or underfilling of the bags.

5.Sealing: Once the bag is filled with the desired volume of liquid, the filling nozzle is retracted, and the tap or valve is closed. The machine then performs the sealing process to secure the bag and prevent any leakage. Sealing methods can include heat sealing, ultrasonic sealing, or other sealing mechanisms.

6.Bag Removal: After sealing, the filled bag is detached from the machine, and a new bag is prepared for the next filling cycle. Some machines may have an automatic bag removal system, while others require manual intervention to remove the filled bag.

How many types of Bag-in-Box (BIB) filling machine?

There are several types of Bag-in-Box (BIB) filling machines available, each designed to cater to different production needs and requirements. The specific types of BIB filling machines can vary based on their level of automation, capacity, and functionality. Here are some common types:

1.Manual BIB Filling Machines:

These machines are operated manually and are suitable for small-scale or low-volume production.

They require manual control for filling, sealing, and other processes.

Manual BIB filling machines are cost-effective and suitable for businesses with limited production needs.

2.Semi-Automatic BIB Filling Machines:

Semi-automatic machines offer a combination of manual and automated functions.

They typically require some operator intervention but also incorporate automation for filling, sealing, and other processes.

These machines are suitable for medium-sized businesses with moderate production volumes.

3.Aseptic BIB Filling Machines:

Aseptic BIB filling machines are specialized equipment designed for aseptic or sterile filling of BIB bags.

They incorporate features such as sterilization systems, controlled environments, and sterile product supply to ensure the preservation of product quality and prevent contamination.

Aseptic BIB filling machines are commonly used in industries that require long shelf life and strict hygiene standards.

It's important to note that the availability of these types of BIB filling machines may vary based on manufacturers and specific requirements. Businesses should consider factors such as production volume, level of automation, and the nature of the product being filled when selecting the most suitable BIB filling machine for their operations.

Benifits of BIB filling machine

Bag-in-Box (BIB) packaging has become increasingly popular in the food and beverage industry due to its numerous advantages. This innovative packaging solution offers convenience, extended shelf life, and environmental sustainability. In this article, we will explore the benefits of BIB packaging for liquid products, highlighting why businesses should consider adopting this packaging format.

1.Extended Shelf Life:

One of the key benefits of BIB packaging is its ability to extend the shelf life of liquid products. The BIB bags are designed to provide an airtight seal, preventing oxygen and light from degrading the product's quality. This significantly reduces the risk of spoilage, allowing products to stay fresh for an extended period. The aseptic filling process further enhances shelf life by maintaining the sterility of the contents, making BIB packaging ideal for perishable products such as juices, wines, and dairy.

2.Convenient and User-Friendly:

BIB packaging offers convenience and ease of use for both consumers and businesses. The integrated tap or valve allows for controlled dispensing, eliminating the need for additional pouring or measuring utensils. The bags are lightweight and portable, making them ideal for on-the-go consumption or outdoor events. BIB packaging also reduces product wastage as the bags can be squeezed to extract every last drop, minimizing leftovers and ensuring efficient product usage.

3.Cost-Effective:

BIB packaging presents cost-saving advantages for businesses. The packaging materials used, such as flexible films and sturdy cardboard boxes, are generally more affordable compared to traditional rigid containers. BIB bags are lightweight and compact, reducing transportation and storage costs. Additionally, the efficient filling process of BIB packaging minimizes labor and production time, leading to improved operational efficiency and cost-effectiveness.

4.Environmental Sustainability:

Sustainability is a growing concern for both businesses and consumers. BIB packaging offers several eco-friendly advantages. The reduced weight and compactness of BIB bags result in lower transportation costs and carbon emissions. The packaging materials are recyclable, and some suppliers offer programs for the collection and recycling of used bags, promoting a circular economy. Furthermore, BIB packaging eliminates the need for additional packaging layers, such as glass or plastic bottles, reducing overall waste generation.

5.Versatility:

BIB packaging is versatile and can accommodate a wide range of liquid products. It is suitable for beverages such as wines, juices, soft drinks, and water, as well as dairy products, liquid food ingredients, and even industrial liquids. BIB bags come in various sizes, allowing businesses to offer different portion options to cater to diverse consumer needs. The customizable branding and labeling options on the packaging provide a platform for effective marketing and product differentiation.

Conclusion:

Bag-in-Box (BIB) packaging offers numerous benefits for liquid products, making it a compelling choice for businesses seeking convenience, extended shelf life, cost savings, and sustainability. With its user-friendly design, extended product freshness, and reduced environmental impact, BIB packaging is revolutionizing the way liquid products are packaged and consumed. Embracing BIB packaging can provide a competitive edge, enhance customer satisfaction, and contribute to a more sustainable future in the food and beverage industry.

Bag-in-Box (BIB) bags size and bag loading weigh:

Bag-in-Box (BIB) bags come in various sizes and weights to accommodate different liquid products and consumer needs. The specific size and weight of BIB bags can vary depending on the manufacturer and the intended application. Here are some common sizes and weight ranges for BIB bags:

1.Small size:

Capacity: 1-5 liters (0.26-1.32 gallons)

Weight Range: Approximately 50-200 grams (1.76-7.05 ounces)

These smaller BIB bags are commonly used for personal-sized portions, such as single-serve beverages or condiments.

2.Medium Sizes:

Capacity: 5-10 liters (1.32-2.64 gallons)

Weight Range: Approximately 150-400 grams (5.29-14.11 ounces)

Medium-sized BIB bags are often used for household or commercial applications, such as family-sized beverages, cooking ingredients, or cleaning liquids.

3.Large Sizes:

Capacity: 10-20 liters (2.64-5.28 gallons)

Weight Range: Approximately 250-600 grams (8.82-21.16 ounces)

These larger BIB bags are suitable for bulk quantities of liquids, commonly used in industrial or foodservice applications.

4.Extra-Large Sizes:

Capacity: 20+ liters (5.28+ gallons)

Weight Range: Varies depending on capacity, typically 500 grams (17.64 ounces) and above.

Extra-large BIB bags are used for high-volume applications, such as large-scale beverage dispensing or industrial liquid packaging.

It's important to note that the weight of the BIB bags can vary based on factors such as the thickness of the bag material, additional components (such as taps or valves), and the specific requirements of the product being packaged. The weight range provided above serves as a general guideline and may vary between manufacturers and specific bag designs.

Additionally, manufacturers may offer custom sizes and weight options based on their clients' requirements, allowing for flexibility in meeting specific packaging needs.

Contact: iForcePack

Phone: +86-198 7511 8892

E-mail: info@iforcepack.com

Add: J101,Haitang,Siji huacheng, Bantian Street, Longgang District, Shenzhen, Guangdong, China